Wesley

I wasn’t at Chlorine long, when the opportunity came up for a job at EO. This plant was considered the "retirement" home, because the process was so clean with few noxious chemicals that it ran forever without problems. My supervisor there was a guy named Wes, and he was the SuperTech It was at this time that operations voted on the proposal to move from 7 day, 8 hour shifts, to 3 day, 12 hour shifts. I voted against it, the other 49 operators voted for it, so it was carried. (To this day I don’t understand why I voted against it, because after my first week of 12 hour shifts, I just loved the new pattern. We were basically working 3 days, then get 3 days off, then 3 night-shifts, and another 3 days off. I had a long weekend every 3 days!)

Posted on Sunday, July 07, 2019

Joe Cool and the Collapsing Tank

We had this huge tank that held what we called "base-blend" for antifreeze. Basically it was antifreeze without things like dye, anti-foam and detergents in it. The name of the tank was "hundred-by-fifty", which was a reference to it’s dimensions in feet, that is, 100 feet in diameter and 50 feet high. (When I once referred to it by it’s number, D301, I was laughed at, like we all laughed at the Lieutenant in Good Morning Vietnam when he asked if any one wanted a "beverage"). It held 2 million gallons of antifreeze, about what we sold in a year to about 20 big customers like GM, Ford, Turbo, and Imperial Oil. One warm day (the fact it was warm figures prominently in this story) , during the off-season, the decision was made to repaint the tank. Because this would involve sand-blasting the tank, the supervisor of the plant took it upon himself to walk up to the top of the tank and put a plastic bag over the 10 inch vent spout coming off the roof. This was a tank, not a pressure vessel, so a vent was there to keep the tank at atmospheric pressure while we pumped liquid into and out of it. Because of it’s size, it was located away from our own tank farm of about 40 tanks, and was close to a neighboring plant, Herbicides. It was actually right at the back door of their production floor, close to the control room.

The plastic bag that the supervisor had used was a very tough, thick plastic, used to bag one of the Herbicides chemicals. He put the bag over the vent, securing it with black tape to keep it from falling off. That night it rained. A cool, cool rain.

Sunday, July 07, 2019

To give you an idea how "Joe Cool" Wes was, I’ll relate a story of an event at EO that could have been much more serious than it was.We had this huge tank that held what we called "base-blend" for antifreeze. Basically it was antifreeze without things like dye, anti-foam and detergents in it. The name of the tank was "hundred-by-fifty", which was a reference to it’s dimensions in feet, that is, 100 feet in diameter and 50 feet high. (When I once referred to it by it’s number, D301, I was laughed at, like we all laughed at the Lieutenant in Good Morning Vietnam when he asked if any one wanted a "beverage"). It held 2 million gallons of antifreeze, about what we sold in a year to about 20 big customers like GM, Ford, Turbo, and Imperial Oil. One warm day (the fact it was warm figures prominently in this story) , during the off-season, the decision was made to repaint the tank. Because this would involve sand-blasting the tank, the supervisor of the plant took it upon himself to walk up to the top of the tank and put a plastic bag over the 10 inch vent spout coming off the roof. This was a tank, not a pressure vessel, so a vent was there to keep the tank at atmospheric pressure while we pumped liquid into and out of it. Because of it’s size, it was located away from our own tank farm of about 40 tanks, and was close to a neighboring plant, Herbicides. It was actually right at the back door of their production floor, close to the control room.

The plastic bag that the supervisor had used was a very tough, thick plastic, used to bag one of the Herbicides chemicals. He put the bag over the vent, securing it with black tape to keep it from falling off. That night it rained. A cool, cool rain.

Send Comments

The Big Disaster Was A Disaster

One operator jumped off the back of the truck and made the connection to the hydrant, as the fire engine kept moving forward to unravel the 1-1/2 inch hose. I grabbed the nozzle and ran out to the "fire". As I opened the hose the pressure was so great it started to push me around so I yelled for backup, which should have been automatic. I get 2 guys behind me as I open the nozzle full bore, trying to put out that damn smoke bomb! Just then we get a call on the radio that there’s some kind of pseudo-explosion at the Chlorine Plant. The fire chief who should have been directing us at the scene was the one barking out the orders from some vantage point he had where he could see everything. Well the two operators figured the "explosion" was more important than the fire, so they just walked away! So here I am, hanging on to this violent snake that’s pushing me all over the ground. It was like a silent movie, as this hose tossed me around like a dish-rag, to and fro, to and fro. I was trying to stay on the ground because the hose was pushing me up in the air, and as a result was pushing me away from the nozzle. I couldn’t reach it to shut it off. I screamed at those idiots who left me to come back. Fortunately someone with some common sense closed off the valve at the source end. Man what a ride that was!

Next, I got the call that some guy was trapped at the top of the HCL tower and had to be rescued. Because of the "gas release" I had to wear breathing apparatus. I donned my Scott Pac and ran up the 3 flights of stairs only to find this huge millwright laying there, pretending he had succumbed to the gas. It would be necessary for me to lift this 250 pound dead-weight and carry him down the stairs. I radioed that I needed help and whether there was noise over the radio and I couldn’t get through, or I was told there was no one available, I didn’t get help. Now if this guy had really been overcome by chlorine gas I probably could have assumed he was dead and left him there. Or pushed him off the tower. Alas, this was all for fun, and he wanted very much to enjoy a coffee break after this silly exercise. So I asked him if he could walk, because if I tried to carry him, we’d both be rolling down the stairs. Miraculously he was revived, and he helped me down the stairs.

That had to be the most grueling and harrowing work I’ve ever done, in so short a space of time. Lucky I was young and in shape or I might have been one of the real victims.

Monday, July 08, 2019

On a full-scale plant-wide disaster drill one day I was the unfortunate soul who was on shift at the EO Plant, right across from the fire hall. When the alarm went off I wanted to just crawl into a hole, but realizing I couldn’t "not show up", I responded. I opened the door to the fire hall just as the operator from Herbicides showed up and jumped in the cab of the fire engine. Our first "event" was a fire. Talk about realistic: they had a smoke bomb in the middle of an open field that we were somehow supposed to put out. Don’t those things work underwater?One operator jumped off the back of the truck and made the connection to the hydrant, as the fire engine kept moving forward to unravel the 1-1/2 inch hose. I grabbed the nozzle and ran out to the "fire". As I opened the hose the pressure was so great it started to push me around so I yelled for backup, which should have been automatic. I get 2 guys behind me as I open the nozzle full bore, trying to put out that damn smoke bomb! Just then we get a call on the radio that there’s some kind of pseudo-explosion at the Chlorine Plant. The fire chief who should have been directing us at the scene was the one barking out the orders from some vantage point he had where he could see everything. Well the two operators figured the "explosion" was more important than the fire, so they just walked away! So here I am, hanging on to this violent snake that’s pushing me all over the ground. It was like a silent movie, as this hose tossed me around like a dish-rag, to and fro, to and fro. I was trying to stay on the ground because the hose was pushing me up in the air, and as a result was pushing me away from the nozzle. I couldn’t reach it to shut it off. I screamed at those idiots who left me to come back. Fortunately someone with some common sense closed off the valve at the source end. Man what a ride that was!

Next, I got the call that some guy was trapped at the top of the HCL tower and had to be rescued. Because of the "gas release" I had to wear breathing apparatus. I donned my Scott Pac and ran up the 3 flights of stairs only to find this huge millwright laying there, pretending he had succumbed to the gas. It would be necessary for me to lift this 250 pound dead-weight and carry him down the stairs. I radioed that I needed help and whether there was noise over the radio and I couldn’t get through, or I was told there was no one available, I didn’t get help. Now if this guy had really been overcome by chlorine gas I probably could have assumed he was dead and left him there. Or pushed him off the tower. Alas, this was all for fun, and he wanted very much to enjoy a coffee break after this silly exercise. So I asked him if he could walk, because if I tried to carry him, we’d both be rolling down the stairs. Miraculously he was revived, and he helped me down the stairs.

That had to be the most grueling and harrowing work I’ve ever done, in so short a space of time. Lucky I was young and in shape or I might have been one of the real victims.

Trapping Steam

We had about 200 steam traps in the plant but the job of checking them was made easier by having them grouped together in big wood cabinets. There could be as many as 20 traps in one cabinet, or as few as 4 or 5. In many cases, there was no cabinet and the trap was just sitting on a pipe, at the end of a steam tracing. I checked the traps with a water bottle by squirting the trap. If it vaporized quickly, it signified the trap was hot, and therefore working because there was hot condensate going through it. A non-working trap would not evaporate the water and one could put his hand on it This was a bad thing.

A cold trap could be the result of a faulty trap, something that could be checked and fixed quite easily. It did mean we had to find the steam source and shut it off. Doing so and forgetting to turn it back on could be disastrous, as product lines could freeze. All our vessels and outside pipes had to be insulated and heat traced. This "trace" was a copper pipe that had steam flowing inside of it and was wrapped around a tank or other vessel, or simply ran parallel to the pipe. If the trap failed, or if the steam was somehow cutoff to the trace, it would freeze, causing the product inside the pipe to freeze. Of course glycols weren’t too much of a problem, because after all, they were antifreeze, but the amines had real high freeze points. (EG. DEA froze at about 75-80 deg F). If this happened, our process could fail, or at least prevent us from pumping the product into tank cars or trucks.

Finding a frozen steam trap meant getting a probe that fit on the end of a high pressure steam hose, and shoving this probe into the insulation around the frozen pipe at various spots along it’s length. We would start at the trap end, and if the trap was actually functioning, the steam probe would thaw the ice in the copper line, and start dumping the condensate. Half an hour later we would move the lance (as the probe was called), further away from the trap to thaw another section of pipe. Almost without failure, it would require some high-line work because almost all the pipes that had to be traced went between buildings on this structure.

One day, in summer, I was helping a newly hired draftsman update the drawings of the plant, and this necessitated crawling around on the pipes high above the plant floor. After crawling along for awhile, the draftsman decided to sit down so he could make a note in his notebook. Well, he sat on one of these heat traces that was not covered by any insulation. Boy, did he ever scream. The trace he sat on was fed by 150 pound (pressure) steam, which gave a line temperature of about 200 degrees Celsius. He really got a good buttock burn. Not that I saw it or anything…

Monday, July 08, 2019

Besides my regular duties, previously mentioned, I had to check steam traps throughout the plant in winter. These things used thermodynamics of steam to operate. In order to obtain the maximum heating value in the steam, we couldn’t just let the steam flash through a pipe or heat trace, we had to hold it there until it condensed into water. At this point, the steam couldn’t give up any more heat. This was the job of the steam trap, to hold the steam in, but let the condensate out. The condensate, since it was pure distilled water was reclaimed and used in other parts of the process, like blending antifreeze.We had about 200 steam traps in the plant but the job of checking them was made easier by having them grouped together in big wood cabinets. There could be as many as 20 traps in one cabinet, or as few as 4 or 5. In many cases, there was no cabinet and the trap was just sitting on a pipe, at the end of a steam tracing. I checked the traps with a water bottle by squirting the trap. If it vaporized quickly, it signified the trap was hot, and therefore working because there was hot condensate going through it. A non-working trap would not evaporate the water and one could put his hand on it This was a bad thing.

A cold trap could be the result of a faulty trap, something that could be checked and fixed quite easily. It did mean we had to find the steam source and shut it off. Doing so and forgetting to turn it back on could be disastrous, as product lines could freeze. All our vessels and outside pipes had to be insulated and heat traced. This "trace" was a copper pipe that had steam flowing inside of it and was wrapped around a tank or other vessel, or simply ran parallel to the pipe. If the trap failed, or if the steam was somehow cutoff to the trace, it would freeze, causing the product inside the pipe to freeze. Of course glycols weren’t too much of a problem, because after all, they were antifreeze, but the amines had real high freeze points. (EG. DEA froze at about 75-80 deg F). If this happened, our process could fail, or at least prevent us from pumping the product into tank cars or trucks.

Finding a frozen steam trap meant getting a probe that fit on the end of a high pressure steam hose, and shoving this probe into the insulation around the frozen pipe at various spots along it’s length. We would start at the trap end, and if the trap was actually functioning, the steam probe would thaw the ice in the copper line, and start dumping the condensate. Half an hour later we would move the lance (as the probe was called), further away from the trap to thaw another section of pipe. Almost without failure, it would require some high-line work because almost all the pipes that had to be traced went between buildings on this structure.

One day, in summer, I was helping a newly hired draftsman update the drawings of the plant, and this necessitated crawling around on the pipes high above the plant floor. After crawling along for awhile, the draftsman decided to sit down so he could make a note in his notebook. Well, he sat on one of these heat traces that was not covered by any insulation. Boy, did he ever scream. The trace he sat on was fed by 150 pound (pressure) steam, which gave a line temperature of about 200 degrees Celsius. He really got a good buttock burn. Not that I saw it or anything…

Reggie And His Toy Fire Engine

Because we didn’t want to have the usual boring practice, we invented games using safety equipment. For example, we practiced putting on a Scott Air Pac. Without help, we could take one out of a case, put it on and start breathing air from the tank within 10 seconds. This was typically a 60 second job if you had to think about it.

Putting on a full rubber suit with a Scott Air Pac on was just as fun. It was almost a tradition for some clown outside the suit to flip open the bypass valve of the Pac inside the suit. This had the effect of pressurizing the rubber suit until it ballooned up like the Michelin tire man.

Monday, July 08, 2019

As operators we all had to take part in safety training, which included fire drills with a real fire engine. One day, with a rookie driver (Reg) at the wheel, we pretended we were responding to a fire at Water Treatment. This guy was crazy. I’m on the back hanging on to the bar, just like in the movies, and Reg is driving the fire engine like it’s a go-kart! We went flying around these 20 MPH corners, on gravel, at about 50MPH. One corner he took so fast I’m convinced to this day that the tires on one side of the big machine came off the ground! It scared the living hell out of me. More than THE HAND incident!Because we didn’t want to have the usual boring practice, we invented games using safety equipment. For example, we practiced putting on a Scott Air Pac. Without help, we could take one out of a case, put it on and start breathing air from the tank within 10 seconds. This was typically a 60 second job if you had to think about it.

Putting on a full rubber suit with a Scott Air Pac on was just as fun. It was almost a tradition for some clown outside the suit to flip open the bypass valve of the Pac inside the suit. This had the effect of pressurizing the rubber suit until it ballooned up like the Michelin tire man.

Alarms

We never did water-tricks at EO; I’m not sure why not. Wes told the story about some guys having water fights with the high-pressure water-monitors at the Herbicides Plant. They hit the windows on the production floor and blew them all to hell!

Monday, July 08, 2019

Another favourite was waiting for the SuperTech to go to the washroom, then run to the control panel and pull one of the alarms out, then push it back in. This kept the alarm sounding it’s horn and flashing it’s light, something the SuperTech couldn’t ignore. Once he ran from the washroom, usually belting up his pants or zipping his fly, he would cancel the alarm. When the light went out, he knew it wasn’t a valid alarm condition, and listening to the giggling coming from the back of the panel, knew he had been had.We never did water-tricks at EO; I’m not sure why not. Wes told the story about some guys having water fights with the high-pressure water-monitors at the Herbicides Plant. They hit the windows on the production floor and blew them all to hell!

It’s Snowing!

Monday, July 08, 2019

At EO one of my first tricks was getting onto the high-line, a structure that supports all the pipes that go from building to building , with a big box of snow. Then, using my radio, I called the SuperTech out to one of the buildings. As soon as I saw the door open, I dumped the snow. Unfortunately, snow doesn’t fall as swiftly as water, and the guy saw the snow coming and jumped out of the way. Damn.

"Not Functioning Good"

I got a hernia while working at EO, an aggravated injury I first got a few years before when I worked for the City of St.Albert hauling garbage cans. When I told Dick about this and that I would be in hospital for 11 days (that’s right, 11 days. Now they just cut, hand out band-aids and send you on your way), he was quite concerned. Then I mentioned recuperation time. All this time off was a concern for Dick because he’d have to pay someone overtime while I was gone. I stayed home for about a week after the operation when Dick phones and asks when I can come back. Fool that I was, I said I was "pretty good" and could come back in a day or two. Dick was quite happy with that. When I returned I only took stairs one at a time instead of my usual three, and managed to not pull any stitches out.

Monday, July 08, 2019

At one of the displays we set up, (a small control loop mounted on a sheet of plywood) Dick was proudly showing how the loop worked to a fresh group of families that included children. When he was finished with the demonstration he asked for questions. One small boy who looked past the demonstration to a control panel device that had a tag on it asked "What does NFG mean?" All the plant people that were there knew what the letters meant, N for no, G for good, and the F-word in the middle, so we were quite amused when Tricky Dicky replied "Not Functioning Good". He got a good laugh from those who knew the acronym, and a polite thank-you from the little boy.I got a hernia while working at EO, an aggravated injury I first got a few years before when I worked for the City of St.Albert hauling garbage cans. When I told Dick about this and that I would be in hospital for 11 days (that’s right, 11 days. Now they just cut, hand out band-aids and send you on your way), he was quite concerned. Then I mentioned recuperation time. All this time off was a concern for Dick because he’d have to pay someone overtime while I was gone. I stayed home for about a week after the operation when Dick phones and asks when I can come back. Fool that I was, I said I was "pretty good" and could come back in a day or two. Dick was quite happy with that. When I returned I only took stairs one at a time instead of my usual three, and managed to not pull any stitches out.

Family Day

Every year we had Family Day, where our families were allowed to come in and tour the plant. For the event we had to clean up all the areas to be visited like control rooms, production areas and so forth. We had special displays to illustrate process control in general, or a particular process that we duplicated somewhere in the plant, though on a bigger scale. Areas were roped off to guide the visitors around sensitive or dangerous areas.

We had contests. One of my ideas for a contest was to guess the height of our largest distillation column, which was 113 feet high. The prize, as dictated by Dick, was 1 gallon of antifreeze. I thought this was pretty silly to give a prize of only 1 gallon of antifreeze when we had 2 million gallons of the stuff in the crinkle tank. (Some operators filled 45 gallon barrels of the stuff and took it home.) One gallon was barely enough to replace the antifreeze in an engine with a 50-50 mix. I won. We gave the winner 5 gallons.

Monday, July 08, 2019

Our boss at EO was a fairly smart engineer, older than both Wes and I. Dick was a small fellow with gray/black hair and thick eye brows of the same color. He looked creepy and had a temper, so we all stayed away from him. I was always sheltered by Wes because he was the guy I reported to for day-to-day activities, and didn’t have to talk to Dick about process or production problems. That was Wes’s job.Every year we had Family Day, where our families were allowed to come in and tour the plant. For the event we had to clean up all the areas to be visited like control rooms, production areas and so forth. We had special displays to illustrate process control in general, or a particular process that we duplicated somewhere in the plant, though on a bigger scale. Areas were roped off to guide the visitors around sensitive or dangerous areas.

We had contests. One of my ideas for a contest was to guess the height of our largest distillation column, which was 113 feet high. The prize, as dictated by Dick, was 1 gallon of antifreeze. I thought this was pretty silly to give a prize of only 1 gallon of antifreeze when we had 2 million gallons of the stuff in the crinkle tank. (Some operators filled 45 gallon barrels of the stuff and took it home.) One gallon was barely enough to replace the antifreeze in an engine with a 50-50 mix. I won. We gave the winner 5 gallons.

Car 54, Where Are You?

I carried a radio so that I could be contacted in emergencies. One day, Tricky Dicky, the plant manager, called me on the radio in a most asinine and confusing way. We used to follow a certain protocol to call someone so there would be no confusion as to who wanted who. Sort of like the military using the phonetic alphabet to eliminate any ambiguity in the transmission. Instead of saying "Bob Found, are you by?" which was standard, he said something like "Dick Wilson for EO operator". What the hell was that about? I didn’t answer because I didn’t know if it was for me, because there was another operator on shift at the time. He called again and again until I finally answered. He gave me hell for not answering, I defended myself by telling him he didn’t use the radio correctly. When I got back to the plant, all the guys in the control room were snickering when I entered, so obviously they heard both sides of the conversation.

Tuesday, July 09, 2019

Shortly after this fiasco of me operating Water Treat while my SuperTech did the operator job at EO, management decided to put one person in Water Treat, on day-shift only to take care of the menial tasks. Then we only had to check WT once or twice a shift to make sure the alum feeders weren’t plugging up, or the chlorine ran out.I carried a radio so that I could be contacted in emergencies. One day, Tricky Dicky, the plant manager, called me on the radio in a most asinine and confusing way. We used to follow a certain protocol to call someone so there would be no confusion as to who wanted who. Sort of like the military using the phonetic alphabet to eliminate any ambiguity in the transmission. Instead of saying "Bob Found, are you by?" which was standard, he said something like "Dick Wilson for EO operator". What the hell was that about? I didn’t answer because I didn’t know if it was for me, because there was another operator on shift at the time. He called again and again until I finally answered. He gave me hell for not answering, I defended myself by telling him he didn’t use the radio correctly. When I got back to the plant, all the guys in the control room were snickering when I entered, so obviously they heard both sides of the conversation.

Pneumatics Were a Pain

Tuesday, July 09, 2019

When I worked at EO as an operator, it was also my duty to go to the Water Treatment Plant to check it out because there was no longer operators there. One time on a day shift, I had to fill the brine tank with salt for regenerating the Zeolite softeners. Simultaneously a number of 4500 gallon tank trucks were lining up for loading, so the SuperTech had to do that job while I worked at Water Treat. He didn’t like this at all. Not so much that it was an operator’s job, but because he couldn’t watch the plant. In those days all the control instruments were pneumatic, not electronic, and the alarm panel was not too sophisticated. The latter was relay-operated and the unit failed continuously. Nowadays with distributed control systems that are all computer-controlled, and with solid state electronics for alarms, there is much flexibility in how a plant is run and controlled. Alarms are easier to prioritize so that only the important ones sound in the plant, and they can have different tones for different emergencies. Now, too, if such a situation arose, the operator can walk up to a computer terminal in a remote area and see just what the problem is.

Where Were You In ’72?

Tuesday, July 09, 2019

When Henderson scored the winning goal for Team Canada in the first Russia-Canada hockey series I was standing at the window in the lunch room with Wes, having a coffee and a smoke, listening to the game on the radio. I remember Wes saying "It’s all over, they’ll have to settle for a tie, they can’t win". Ahhhh. Famous last words. We all know that with only a few minutes left in the game, Henderson scored to win the game and the series. Wes and I were hootin’ and hollerin’ like we had won the lottery. The war was over, and Canada won by beating the Russians. Man, the pride we felt. That 1972 team did more for Canadian unity than any government ever did. My little hockey-player-son was born in 1972, so obviously I was elsewhere in ’72…

Hard Head, Tough Crotch

The second "accident" was when I was inspecting a tank car for loading with antifreeze. As I bent over to look inside, the 3" metal loading nozzle, swung down and hit me on the back of my hard hat, knocking it off and into the tank. Had I not been wearing the hard hat it would have hit me right in the back of the head and probably knocked me unconscious. I would have fallen into the tank and been part of some guys car engine somewhere in North America! I retrieved my hat with some wire and then reported this incident. I fully expected to win the "Golden Hat" Award but they didn’t even consider it. Jerks. It was probably just a regular hard hat spray painted gold in the shop anyway.

The Golden Hat was an industry-standard award given out by various industries to employees who were saved from serious injury because they were wearing a hard hat. (In Quebec, they call it the Golden Toque, in South America the Golden Fedora…). I once saw one at Dow and it was actually a very nice shiny gold plated hat, it wasn’t spray painted. I wanted a hat and was willing to get a bump on the head to get one. I should have got the Golden Crotch award too.

Tuesday, July 09, 2019

I had two accidents at EO, but was not injured. I reported both of these because I could have been killed on either. These types of accidents were called near-misses. The first accident was when I was at the top of the all-steel loading ramp and about to come down by the stairs. Because we always ran a steam purge on the loading lines to prevent freeze-up (this was the amine loading ramp: di-ethanolamine froze at 80 deg F.) the blowing steam had made the stairs a virtual skating rink on a slope. I had my hands on the handrail and took my first step, knowing that it was slippery. Despite my trepidation, I slid down that ramp with an acceleration of 1 G: "there weren’t no friction here!" At the very bottom, my right leg stuck out and wrapped around the bottom hand rail support. Luckily I didn’t get that steel bar up my crotch or I’d be writing with a small font like this.The second "accident" was when I was inspecting a tank car for loading with antifreeze. As I bent over to look inside, the 3" metal loading nozzle, swung down and hit me on the back of my hard hat, knocking it off and into the tank. Had I not been wearing the hard hat it would have hit me right in the back of the head and probably knocked me unconscious. I would have fallen into the tank and been part of some guys car engine somewhere in North America! I retrieved my hat with some wire and then reported this incident. I fully expected to win the "Golden Hat" Award but they didn’t even consider it. Jerks. It was probably just a regular hard hat spray painted gold in the shop anyway.

The Golden Hat was an industry-standard award given out by various industries to employees who were saved from serious injury because they were wearing a hard hat. (In Quebec, they call it the Golden Toque, in South America the Golden Fedora…). I once saw one at Dow and it was actually a very nice shiny gold plated hat, it wasn’t spray painted. I wanted a hat and was willing to get a bump on the head to get one. I should have got the Golden Crotch award too.

What a Relief

Tuesday, July 09, 2019

After two years as an operator, I was made SuperTech Relief. I was paid more, and had an operator working for me. It was pretty neat. During a shutdown I was Relief, and because I wanted to impress my superiors, I made sure that we did as much of the task list that was given to us as possible. My operator was bitching and complaining that we weren’t supposed to work so hard on night shift, but I persisted. I had to kick his ass to do some work. I still had to do most of it because he was too damn lazy.

Pump Many-folds

Tuesday, July 09, 2019

Most of the antifreeze tanks were 40,000, with a couple at 60,000 gallons. To pump from one tank to another or from blend tanks to any tank, or from any tank to the loading platform required some well-thought out piping and valving. Most of the pumps, had large manifolds with 4 to 10 valves mounted on them whose piping lead to the various tanks. I remember once having to get some material from one location to another, and was told by the SuperTech that it wasn’t possible, that I would have to pump to one tank, and hook up some temporary hoses to perform the transfer. I knew where every pipe went, so after a little survey, came up with my plan. I had to manipulate 22 valves and put flow backwards through a pump, but I did it. I pointed it out to an incredulous SuperTech who agreed then that it was possible. Ahhh…give me a challenge. Actually I was lazy, I just didn’t want to go through the effort of getting those big hoses hooked up.

TEA Fire

Tuesday, July 09, 2019

We had a fire in the TEA tar pot once too. Some product had come in contact with a hot steam trace around the pot and started the top of it on fire. I noticed it first and calmly said to Wes, "is that a flame I see on top of the pot?" He looked out and said yes indeed, it was. So he ran up there and put it out. No big deal. The supervisors thought it was pretty big deal because they didn’t see how "subdued" the fire really was. It was about as violent as those little methanol heaters they give you in a restaurant to keep the butter melted for your lobster. Considering how all the glycols are flammable, I guess the supervisors had some reason for concern.

MEG Ryan, er… Tower

I also went IN this tower, just for the experience. The plant had it’s annual "turnaround" and the tower had been opened for inspection and moving of some of the trays inside. The tower was about 4 feet in diameter with an open 18" man-way. Since it was after hours, I asked the Super Tech if I could go inside to check things out. He said, "Sure, why not. The tray you’ll be stepping on supported a 220 pound millwright, so you should be okay". So I crawled in, looked around, pushed up on the bubble-caps in the tray above, pulled on the caps on the tray I was sitting in. How many people do you know can add that to their resume? (Addendum April 2006: I write about a 220 pound millwright like they are a special breed of person that weighs that much. Today, I weigh that much! Obviously I was skinny in my youth, to cast that disparaging comment).

Tuesday, July 09, 2019

I climbed the mono-ethylene glycol (MEG) tower for the hell of it. It was 113 feet high. I remember that because when we had our Family Day at Dow, we ran a contest to guess the height of the tower and I had to look it up on the drawings to get the exact height. This was an easy climb, because for every 20 vertical feet climbed there was a landing half way around the tower. So I could stop and look around on my way up. Never took any pictures. What a fool.I also went IN this tower, just for the experience. The plant had it’s annual "turnaround" and the tower had been opened for inspection and moving of some of the trays inside. The tower was about 4 feet in diameter with an open 18" man-way. Since it was after hours, I asked the Super Tech if I could go inside to check things out. He said, "Sure, why not. The tray you’ll be stepping on supported a 220 pound millwright, so you should be okay". So I crawled in, looked around, pushed up on the bubble-caps in the tray above, pulled on the caps on the tray I was sitting in. How many people do you know can add that to their resume? (Addendum April 2006: I write about a 220 pound millwright like they are a special breed of person that weighs that much. Today, I weigh that much! Obviously I was skinny in my youth, to cast that disparaging comment).

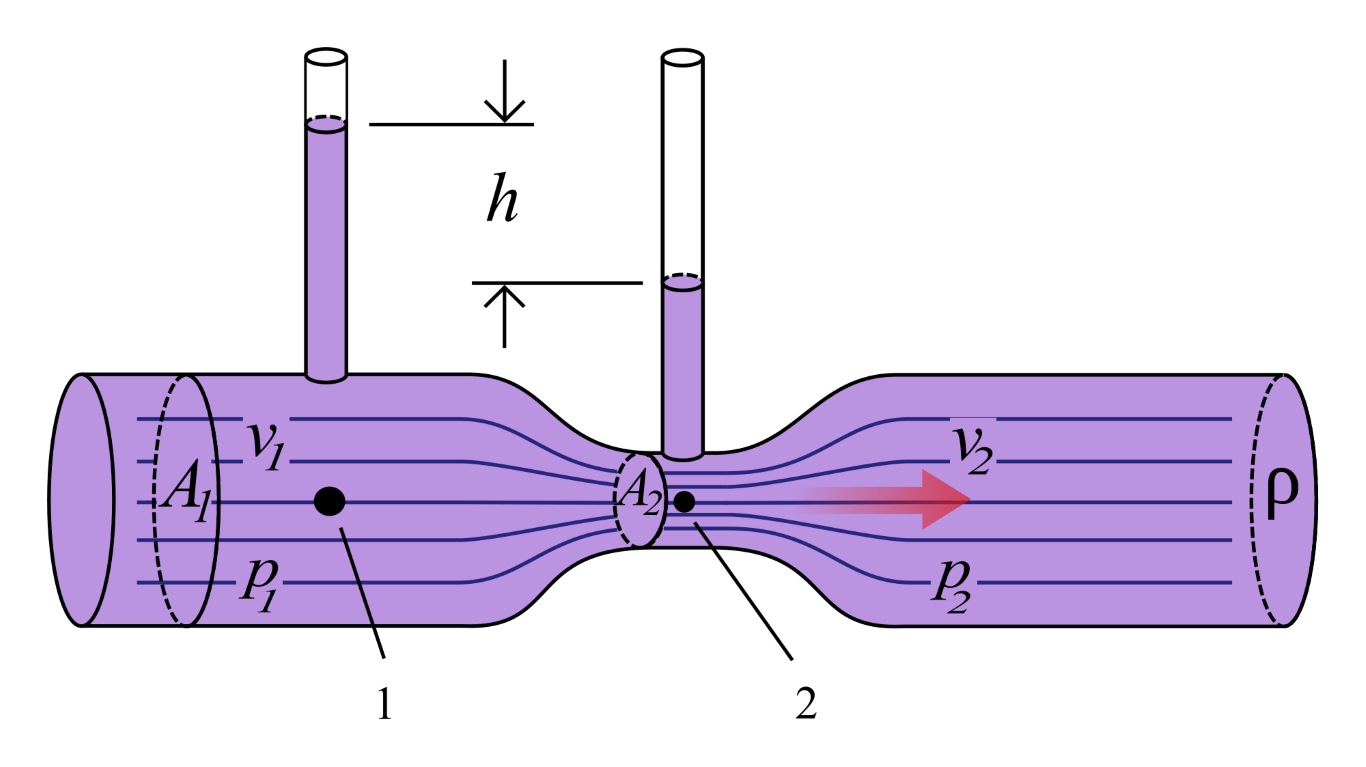

Thank You Mr. Bernoulli

We used high-pressure steam flowing through various injectors (as they were also called) to created a low-pressure zone, that is, a vacuum. This was connected to the 3rd evaporator and the 3 glycol towers. By pulling a vacuum on all the towers, we could reduce the temperature at which the product boiled. The result of this, was less heat needed to boil the product, the vacuum would "suck" product out of the tower (through the condenser), all the while reducing the requirement for steam. Man were they noisy! Extremely maintenance free, for the 3 years I was at EO , we never even looked at these things. They just ran and ran, no need for the Maytag man.

Tuesday, July 09, 2019

One thing I always thought was real neat was how we managed to save steam, reduce boiling temperatures of the products, and move product, all with a simple device with no moving parts. I could make one of these in my shop, it is so simple. It was the venturi.We used high-pressure steam flowing through various injectors (as they were also called) to created a low-pressure zone, that is, a vacuum. This was connected to the 3rd evaporator and the 3 glycol towers. By pulling a vacuum on all the towers, we could reduce the temperature at which the product boiled. The result of this, was less heat needed to boil the product, the vacuum would "suck" product out of the tower (through the condenser), all the while reducing the requirement for steam. Man were they noisy! Extremely maintenance free, for the 3 years I was at EO , we never even looked at these things. They just ran and ran, no need for the Maytag man.

(Daniel Bernouli discovered this effect that led to the venturi invention a century

or so ago. It’s the same principle that explains why airplanes fly and toast

always falls on the floor jam-first.)

Evacuate ! Evacuate!

Wes walked up, briskly, to the top of the tank, saw the bag half sucked in, like some hard-formed plastic salad bowl. He took his knife and stabbed at it, and was greeted with this loud "whoosh" as the air was let back into the tank. When this happened, the tank bounced back out a couple of feet!or

When daylight appeared and we went back for a better look, the tank was the funniest thing you ever saw. It was buckled up just like that turpentine can, only better. Among all the perfectly formed tanks and pipes was this huge accordion! I was curious about the metal thickness, and noticed that where the plates overlapped and were welded (they were not butt-welded), the bottom layer of plates was 1" thick. You would not be able to lift a piece of one foot square 1" metal plate, that’s how heavy this was! As I walked up the stairs on the side of the tank, the plate thickness diminished to about ¼" at the top.em

Fortunately, no antifreeze leaked out of the vessel, that is no cracks developed. The Herbicides operators were worried because they had no idea how full this tank was, and indeed, if it had been full, and the tank blew out at the bottom, they probably would have drowned in antifreeze. The tank was that close to them, and the pit around the tank would not have contained the entire contents. When the tank was filled with antifreeze, over the course of the next few months, the tank bounced out a bit more, with only small bumps to indicate it’s traumatic past. ip

The supervisor, though he hadn’t really done anything wrong, was fired. He was approaching retirement age and was really just a figurehead, with not very much actual management duties, so he was "marked" anyway for dismissal. The tank implosion only accelerated his demise..um dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Friday, July 12, 2019

Very late in the evening we got an emergency radio call from the SuperTech at Herbicides saying he was shutting down his plant and evacuating the employees, because 100 by 50 was collapsing! Wes listened to the message, trying to calm the guy down. As he was doing so, he walked, not ran, to the area and saw that the tank wasn’t collapsing, but rather buckling inward. He understood the problem right away: the hot air in the tank was cooled by the rain, reducing the pressure within the tank. Because the vent was "plugged", the pressure couldn’t equalize, and this small pressure differential inside and out was enough to buckle the tank. Just like the high school experiment where the teacher heats a metal turpentine can with the top off, puts the top on, then runs the tank under cold water. The can buckles immediately.Wes walked up, briskly, to the top of the tank, saw the bag half sucked in, like some hard-formed plastic salad bowl. He took his knife and stabbed at it, and was greeted with this loud "whoosh" as the air was let back into the tank. When this happened, the tank bounced back out a couple of feet!or

When daylight appeared and we went back for a better look, the tank was the funniest thing you ever saw. It was buckled up just like that turpentine can, only better. Among all the perfectly formed tanks and pipes was this huge accordion! I was curious about the metal thickness, and noticed that where the plates overlapped and were welded (they were not butt-welded), the bottom layer of plates was 1" thick. You would not be able to lift a piece of one foot square 1" metal plate, that’s how heavy this was! As I walked up the stairs on the side of the tank, the plate thickness diminished to about ¼" at the top.em

Fortunately, no antifreeze leaked out of the vessel, that is no cracks developed. The Herbicides operators were worried because they had no idea how full this tank was, and indeed, if it had been full, and the tank blew out at the bottom, they probably would have drowned in antifreeze. The tank was that close to them, and the pit around the tank would not have contained the entire contents. When the tank was filled with antifreeze, over the course of the next few months, the tank bounced out a bit more, with only small bumps to indicate it’s traumatic past. ip

The supervisor, though he hadn’t really done anything wrong, was fired. He was approaching retirement age and was really just a figurehead, with not very much actual management duties, so he was "marked" anyway for dismissal. The tank implosion only accelerated his demise..um dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Sweetening the North Saskatchewan

Part of my job was to fill tank cars with antifreeze. It took typically a couple of hours to fill a tank car with the loading pumps that we used, so we didn’t stand around and watch. What we did was divide the capacity of the tank car (shown on the side of the car) by the capacity of the pump. I was actually new to the plant and didn’t really know too much about how this worked or the values to use, so I depended on Wes to tell me how long it would take. He came up with an answer of so many minutes, to which we added a safety factor of about 20% where we would have to go visually inspect the tank car to see how full it was. Then we would stay around to top it up. Since this was a tank car operating at atmospheric (unlike liquefied gases like chlorine that were loaded into pressurized vessels), the man-hole in the center top of the car was open, and the loading nozzle just pushed in. The loading pipe was 3" in diameter and when spewing out product did so under good high pressure, so there was a lot of flow. I can’t remember the exact values, but I know it was something like 200 gallons per minute.

So, we started the pump, then went back to the control room for coffee. Close to the allotted time Wes went out to check the tank car, with it’s 20% safety factor built in, and saw that it was overflowing! At 200 gallons per minute! It only took seconds to get to the pump and shut it down, so there was very little loss once Wes saw the overflow. His calculation was wrong because the pump capacity was much more than he thought, so consequently the tank filled up faster than he thought it would. Wes took the tank level readings before and after the "spill" to find out how much went into the car, and how much down the sewer and came up with a loss of 8000 gallons! That’s a lot of radiators! Except for the dye, which we would have added at the "20% to go" mark, the antifreeze was fully blended and exactly what you would buy in a store, in 1 gallon bottles. (Let’s see, at $8.00 a gallon, that’s $64,000!)

The only evidence that "something" happened was an elevated value of "organics" in the effluent, a test done daily on the material flowing to the river. All the antifreeze would have gone to the settling ponds before going to the river, so it most likely reacted with other chemicals and converted into something safer for the environment. Glycol is related, chemically to glucose (sugar) and has a sweet taste to it. (It’s extremely poisonous - Do not do this at home! )

So here was the dilemma: admit there was a spill and either get fired or ridiculed, or admit nothing and try and "bury it". Since being ridiculed was a fate worse than firing or even death, we decided to bury it. Again I had to depend on the wise man to figure out how to do this. I would have just blamed someone else from another plant... What we did was do a bunch of tank transfers from the buckled "100 by 50" into the tank we took the blend out of. Then we transferred that into other tanks. After a few of these transfers, we were convinced that the 8000 gallons was lost somewhere in the "gauging". The reason this worked was because when we took 40,000 gallons out of the 100 foot diameter tank, the tank gauge only dropped 10". Or was it 9-1/2" or 10-1/2"? It was so subjective that it was easy to say the number that would be beneficial to our cause. (This would have been a good scam for anyone wanting to steal antifreeze.) The other tanks were 40,000 gallons capacity and though the error was less pronounced, we could make ¼" disappear, which amounted to a couple hundred gallons.

I always wondered why the ponds never froze over. We were never discovered, and the episode taught us how to calculate better.

Friday, July 12, 2019

Wes also showed his cool after a major chemical spill. He was so cool, that no one ever found out about it. Part of my job was to fill tank cars with antifreeze. It took typically a couple of hours to fill a tank car with the loading pumps that we used, so we didn’t stand around and watch. What we did was divide the capacity of the tank car (shown on the side of the car) by the capacity of the pump. I was actually new to the plant and didn’t really know too much about how this worked or the values to use, so I depended on Wes to tell me how long it would take. He came up with an answer of so many minutes, to which we added a safety factor of about 20% where we would have to go visually inspect the tank car to see how full it was. Then we would stay around to top it up. Since this was a tank car operating at atmospheric (unlike liquefied gases like chlorine that were loaded into pressurized vessels), the man-hole in the center top of the car was open, and the loading nozzle just pushed in. The loading pipe was 3" in diameter and when spewing out product did so under good high pressure, so there was a lot of flow. I can’t remember the exact values, but I know it was something like 200 gallons per minute.

So, we started the pump, then went back to the control room for coffee. Close to the allotted time Wes went out to check the tank car, with it’s 20% safety factor built in, and saw that it was overflowing! At 200 gallons per minute! It only took seconds to get to the pump and shut it down, so there was very little loss once Wes saw the overflow. His calculation was wrong because the pump capacity was much more than he thought, so consequently the tank filled up faster than he thought it would. Wes took the tank level readings before and after the "spill" to find out how much went into the car, and how much down the sewer and came up with a loss of 8000 gallons! That’s a lot of radiators! Except for the dye, which we would have added at the "20% to go" mark, the antifreeze was fully blended and exactly what you would buy in a store, in 1 gallon bottles. (Let’s see, at $8.00 a gallon, that’s $64,000!)

The only evidence that "something" happened was an elevated value of "organics" in the effluent, a test done daily on the material flowing to the river. All the antifreeze would have gone to the settling ponds before going to the river, so it most likely reacted with other chemicals and converted into something safer for the environment. Glycol is related, chemically to glucose (sugar) and has a sweet taste to it. (It’s extremely poisonous - Do not do this at home! )

So here was the dilemma: admit there was a spill and either get fired or ridiculed, or admit nothing and try and "bury it". Since being ridiculed was a fate worse than firing or even death, we decided to bury it. Again I had to depend on the wise man to figure out how to do this. I would have just blamed someone else from another plant... What we did was do a bunch of tank transfers from the buckled "100 by 50" into the tank we took the blend out of. Then we transferred that into other tanks. After a few of these transfers, we were convinced that the 8000 gallons was lost somewhere in the "gauging". The reason this worked was because when we took 40,000 gallons out of the 100 foot diameter tank, the tank gauge only dropped 10". Or was it 9-1/2" or 10-1/2"? It was so subjective that it was easy to say the number that would be beneficial to our cause. (This would have been a good scam for anyone wanting to steal antifreeze.) The other tanks were 40,000 gallons capacity and though the error was less pronounced, we could make ¼" disappear, which amounted to a couple hundred gallons.

I always wondered why the ponds never froze over. We were never discovered, and the episode taught us how to calculate better.

Blending In

I would help out on track whenever tanks were coming in my area. I’ve had to hook up brake lines, apply brakes to a moving train, jump on moving cars as they passed by, and couple and uncouple cars. It was a dangerous job so one had to be careful, especially jumping on a string to apply the brakes. The little Trackmobile just didn’t have enough mass or power to stop a bunch of loaded tank cars, so once it got them moving, they were very hard to stop with the Trackmobile alone. The "Li’ll Engine That Could", couldn’t.

Friday, July 12, 2019

The track crew were the guys that actually blended the antifreeze. These guys were the ones that normally shunted all the tank cars around for filling or dumping. They worked with the railway when the big diesel engines came in to pull the real big strings of cars, but they had a Trackmobile that could move maybe 10 cars around at a time, empty ones that is. There were a few reasons why the track crew blended the batches of antifreeze. One was the fact that they weren’t always shunting cars around, so they had extra time. The other was that track was considered a more demeaning job than operations, and blending antifreeze didn’t tax the neurons that much. Wes and I often blended batches when the track crew wasn’t available. The blend was not a complete batch of antifreeze, it was just a blend of the additives mixed with a little bit of antifreeze. When this small batch of chemicals was warmed up and mixed, it was sent to one of the big storage tanks to mix with the much larger amount (usually a few tank cars worth). Then it was analyzed in the lab, some by me, some by the chemical technicians to make sure it met the customer’s specifications.I would help out on track whenever tanks were coming in my area. I’ve had to hook up brake lines, apply brakes to a moving train, jump on moving cars as they passed by, and couple and uncouple cars. It was a dangerous job so one had to be careful, especially jumping on a string to apply the brakes. The little Trackmobile just didn’t have enough mass or power to stop a bunch of loaded tank cars, so once it got them moving, they were very hard to stop with the Trackmobile alone. The "Li’ll Engine That Could", couldn’t.

Analysis

I had to watch for the first drip, a drip half-way through to determine the "50% point", then the final point. The last one we always missed because we would try and have coffee or a smoke between drips, and just never got back in time. The first drip was the important one anyway…

One day a flask cracked on the heater, causing some of the liquid to drip through to the element. This started a fire which I quickly put out.

Friday, July 12, 2019

As in all the other plants I worked, part of my regular duties was to do chemical analysis of our products. A regular routine was just at the beginning of the shift, getting samples of all the amines and all the glycols. One of the tests I did was boiling points, a procedure that involved putting 100 milli-liters of product in a boiling flask which was put on an electric heater. I had to watch for the first condensed drop of liquid from the boiling liquid and read the inserted thermometer to get the first "boiling point". If this wasn’t on spec, say too low boiling point, we would send the product to recycle or to base blend, depending on what the product was. Too low a boiling point meant we didn’t boil the product enough in the reboilers, or there wasn’t enough reflux. We made changes, then did the analysis again, continuing until it was on spec. If the boiling point was too high, that meant we were boiling it too much and we were giving away heavy molecules. It wasn’t off-spec, just too good a product! So we had to cut back on the steam to the reboiler or increase reflux.I had to watch for the first drip, a drip half-way through to determine the "50% point", then the final point. The last one we always missed because we would try and have coffee or a smoke between drips, and just never got back in time. The first drip was the important one anyway…

One day a flask cracked on the heater, causing some of the liquid to drip through to the element. This started a fire which I quickly put out.

Warts Begone!

A doctor from the local medical clinic would come out about once a month with a thermos bottle (he called it a Dewar flask, but it really WAS a thermos) asking for a refill. They used it for freezing warts off people. Filling the thermos was difficult because the liquid would vaporize as soon as it hit the warm thermos so that you couldn’t see what was going on. A small thermos of liquid nitrogen didn’t weigh much, so about the only way you could tell if anything was inside was by shaking it. There were times where I’m sure I sent the doctor on his way with a thermos with only nitrogen gas in it!

Friday, July 12, 2019

There was a large liquid nitrogen tank near the oxide tanks. We used this material for nitrogen-padding pumps and for purging. A nitrogen pad was a technique for a piston-type pump to smooth out it’s pulsations. A "head" of nitrogen was placed inside a pressure vessel mounted just above the pump output. On the "compression" stroke of the pump, the nitrogen would absorb some of the shock because it was a gas and was compressible, whereas the liquid was not. Then, when the pump was in it’s "suction" stroke, the nitrogen was allowed to expand, pushing out the liquid.A doctor from the local medical clinic would come out about once a month with a thermos bottle (he called it a Dewar flask, but it really WAS a thermos) asking for a refill. They used it for freezing warts off people. Filling the thermos was difficult because the liquid would vaporize as soon as it hit the warm thermos so that you couldn’t see what was going on. A small thermos of liquid nitrogen didn’t weigh much, so about the only way you could tell if anything was inside was by shaking it. There were times where I’m sure I sent the doctor on his way with a thermos with only nitrogen gas in it!

TEA Absorber

Friday, July 12, 2019

We made mono-, di-, and tri-ethanolamines, products used in natural gas plants for scrubbing the hydrogen sulfide out of gas. The worst job at EO was changing out the tri-ethanolamine absorber. This was a vertical tank about the size of a hot water tank with a large opening in the side, covered with a big steel plate. This plate and it’s 20 or so big nuts to hold it on was removed to give us access to the activated carbon inside. After filtering TEA ( pronounced "TEE-EE-AY") for a number of days or weeks, this stuff just reeked with a pungent odor that was barely bearable. We (I say "we" but after being told how to do it by the SuperTech, it was forever-after the job of the lowly operator) would scoop the gooey, smelly carbon out with a small shovel and dump it into a wheelbarrow. It was a real dirty job, and you couldn’t help but get some of that crap on your clothes. After cleaning it out, we washed the filter out, took the top off, added clean carbon and put some "angel-hair" on the top. Angel hair was very soft fiberglass material, and was identical to the stuff you used to be able to buy for decorating Christmas trees. In fact I took some of the stuff home for just that purpose. The angel hair, not the smelly carbon. The absorber was used for maintaining the color spec on the TEA: when it started getting too yellow, we had to change the filter media.

"Idi Amine"

Anhydrous ammonia was wicked stuff. When I offloaded this stuff from tank cars I had to wear a full rubber suit, goggles, rubber gloves and face shield. The ammonia was in pressurized tank cars, so hammer unions and large steel flex hoses were used. When I would drain the hoses after unloading the product, I would let the hoses dump out onto the concrete pad underneath the loading dock.

Friday, July 12, 2019

Amine production was almost identical to glycol production, except instead of reacting ethylene oxide with water, we used anhydrous ammonia. We didn’t have the triple-effect evaporators, but we did have one column that did the same thing. All the towers on the amine side were smaller, because the production was smaller. In fact we ran glycols pretty well all year, but when the amine tanks were full, we would shut down the amine side for a couple weeks at a time.Anhydrous ammonia was wicked stuff. When I offloaded this stuff from tank cars I had to wear a full rubber suit, goggles, rubber gloves and face shield. The ammonia was in pressurized tank cars, so hammer unions and large steel flex hoses were used. When I would drain the hoses after unloading the product, I would let the hoses dump out onto the concrete pad underneath the loading dock.

Is Antifreeze All the Same?

The equipment at EO ran for years without maintenance. Unlike a place like Syncrude that has to pump sand-slurries most of the time, we pumped antifreeze which is slippery like oil. Pumps that had been working non-stop for 20 years were still going. So it was indeed a pleasure to work at EO, where pretty well nothing broke.

The process I mentioned was one half of the plant. On the other half was the amine process. The plant was really laid out that way: when I went out the control room door and entered the process area, on the left was glycols, on the right was amines. As I moved through one building to the next, the same pattern was followed. On the left were all the glycol pumps, on the right the amine pumps. This extended all the way to the loading ramps where I offloaded raw materials from tank cars, or loaded our products into tank trucks and tank cars. Never any confusion as to what pump or what tank belonged to what part of the plant.

cing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Friday, July 12, 2019

We added corrosion inhibitors, anti-foam agents, and dye to base blend, of course, to make antifreeze. The dye had other uses as well: sprinkling it around the toilet seat for some hapless victim was always good for a laugh, especially the red stuff: the guy thought he was dying (well he was dyeing…) This stuff was soooooo potent! Maybe a cupful is all that was required for a 4500 gallon tanker truck. And yes, the antifreeze was 99% the same, there was very little difference in GM, Shell, Canadian Tire, or Imperial Oil brands. Only the color was different. This isn’t to say there was no difference, but the differences were so minuscule to not care about. For example, the only difference between GM’s brand and any other might have been an extra cup of anti-foam, or a different pH level, indicating how much corrosion inhibitor was in the product. This was somewhat disconcerting to my Chevy-loving brother who always bought GM-brand anti-freeze as dictated by his owner’s manual. He paid about 3 times the price too!The equipment at EO ran for years without maintenance. Unlike a place like Syncrude that has to pump sand-slurries most of the time, we pumped antifreeze which is slippery like oil. Pumps that had been working non-stop for 20 years were still going. So it was indeed a pleasure to work at EO, where pretty well nothing broke.

The process I mentioned was one half of the plant. On the other half was the amine process. The plant was really laid out that way: when I went out the control room door and entered the process area, on the left was glycols, on the right was amines. As I moved through one building to the next, the same pattern was followed. On the left were all the glycol pumps, on the right the amine pumps. This extended all the way to the loading ramps where I offloaded raw materials from tank cars, or loaded our products into tank trucks and tank cars. Never any confusion as to what pump or what tank belonged to what part of the plant.

cing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Rocket Fuel

To get the ethylene oxide into the plant we used a special pump to prevent heating of the product which could be a bad thing. Only once when I was operating there did we have anything we could call a "problem". For some reason oxide in the pump wasn’t allowed to recycle back to the tank, and pressure built up in the lines. The heat of the pumping polymerized the oxide in the pump. We had to put the plant on "total recycle" while we took the pump apart and pulled this stringy, gooey substance out of the pump.

I heard a story of someone who got some oxide in his boot. On the way to swelling up to double size, his boot had to be cut off because he couldn’t slip it off normally. This too scared me enough to respect the stuff.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Sunday, July 14, 2019

Rocket fuel. That’s what ethylene oxide ( "oxide") has been used for, and possibly still is, for liquid-fueled rockets. We certainly handled it like it demanded respect. I was told when I first worked there that if either of the two large horizontal tanks "blew", that the plant would be relocated at Sherritt-Gordon, about 5 miles away. I had read of an EO plant in Louisiana that did blow up and destroy the plant. The force of the explosion was so great that it created this immense negative pressure (a vacuum) and when a strong "wind" moved in to replace the missing air, it moved large distillation towers off their huge bolted-down mounts. I saw the pictures, and the towers had been moved towards the explosion. In other words, there was an explosion, followed by an implosion. Both destroyed the plant. Pretty incredible. Convinced me to use the grounding strap whenever I off-loaded the tank cars into the field tanks. We had to use brass tools whenever we worked on any pipe or component that contained "oxide" because brass didn’t cause sparks. More than once I dropped the wrench on top of the tank car, and was glad I was following the rules. We used a brass hammer to make the connections of hoses from tank car to off-loading ramp because the style of connect was called a hammer-union. It was a screw-type fitting, about 2" in diameter, made of stainless steel, and around the periphery of the fitting head were 3 large, very strong looking steel "horns" . This is what we struck with the hammer to insure a leak-free, high-pressure fitting.To get the ethylene oxide into the plant we used a special pump to prevent heating of the product which could be a bad thing. Only once when I was operating there did we have anything we could call a "problem". For some reason oxide in the pump wasn’t allowed to recycle back to the tank, and pressure built up in the lines. The heat of the pumping polymerized the oxide in the pump. We had to put the plant on "total recycle" while we took the pump apart and pulled this stringy, gooey substance out of the pump.

I heard a story of someone who got some oxide in his boot. On the way to swelling up to double size, his boot had to be cut off because he couldn’t slip it off normally. This too scared me enough to respect the stuff.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Getting a Reaction

rem ipsum dolor sit amet, consectetur elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Sunday, July 14, 2019

The oxide was pumped to a reactor which was just a mixing chamber followed by lots of cooling exchangers. Once the oxide was injected into a water stream, it reacted exothermally, creating lots of heat, and we had to cool it real quick and controlled or the reaction would go out of control. (A loss of cooling water would cause the oxide flow to shut off automatically before this could happen). This simple reaction produced ethylene glycol which we flowed through a triple-effect evaporation system to remove the excess water. The output from the 3rd evaporator would go to the big 100 by 50 tank as "base blend", and some was fed to the first distillation column. The glycol was circulated in big heaters called reboilers and the vapours allowed to permeate upwards within the column. This column contained about 80 "bubble-cap" trays that had good product called reflux flowing from one tray to another, side to side, then top to bottom, over the caps. As the vapors moved up the tower, they would push on the bubble caps, causing the vapor to mix with the reflux. By the time the vapour got to the top, it was pure mono-ethylene glycol. The vapour was condensed into a liquid and sent to the mono tank.Lorem ipsum dolor sit amet, consectetur elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Glycol Towers

The last product in the chain was tri-ethylene glycol. The "bottoms" from this tower was something we called tars. It was a black, stinky substance from which no useful product could be obtained. We dumped it into a "tar-pot" just below the tower, and emptied the carcinogenic crud into the river and children’s playgrounds. (We had a special area where we dumped this stuff. I think we even sold some of it for use by some company in their process, like paving materials, or rubber manufacturing.)

Sunday, July 14, 2019

The product at the base of the mono tower was sent to the next tower just beside it, the di-ethylene glycol tower. Here the heavier molecules of glycol were removed, exactly in the same fashion as the mono was produced. The only difference was the tower was smaller because less capacity was needed, and the temperatures needed to do the separation were much higher.The last product in the chain was tri-ethylene glycol. The "bottoms" from this tower was something we called tars. It was a black, stinky substance from which no useful product could be obtained. We dumped it into a "tar-pot" just below the tower, and emptied the carcinogenic crud into the river and children’s playgrounds. (We had a special area where we dumped this stuff. I think we even sold some of it for use by some company in their process, like paving materials, or rubber manufacturing.)